Blockchain is a form of distributed ledger that solves a problem that has long plagued businesses: trust. Simply put, it is a ledger that records transactions. That means it includes all the data that is shared, authenticated, and encrypted by the components in the chain. So, from a business perspective, what benefits does blockchain bring to manufacturers?

The transparency of all transactions in the network – the essence of blockchain is to help build trust with consumers. That is the greatest value that manufacturers aim for. In a blockchain network, all components in the chain can see and verify information at any time.

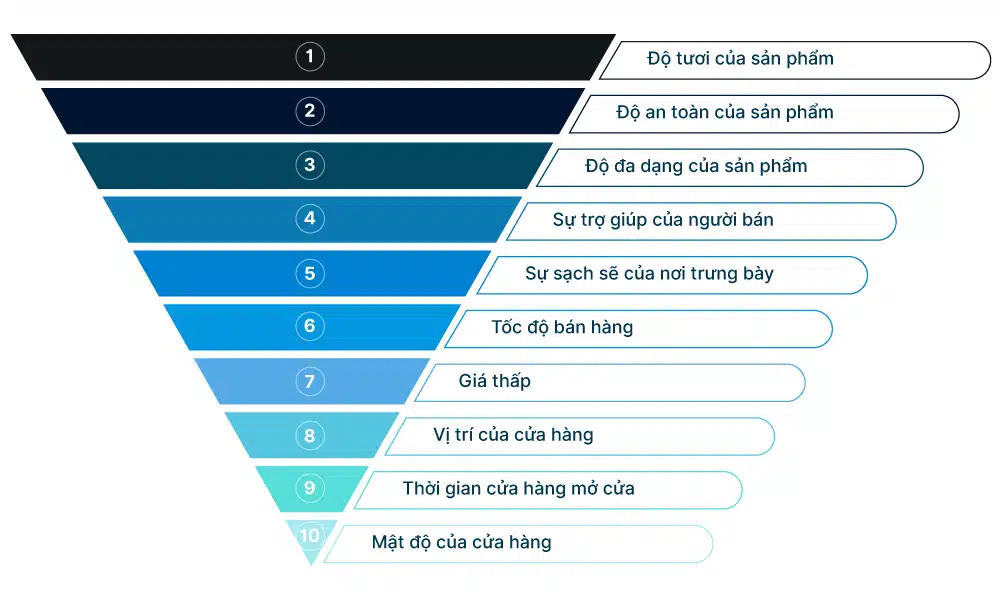

Nowadays, consumers' awareness of safe food consumption is increasingly enhanced, especially in demanding markets such as the US, Europe, and Japan. According to research on food consumer behavior (2), the 10 most important factors influencing consumers' purchasing decisions are ranked in the following order:

The three most important factors in the above 10 factors, including freshness, safety and product price, depend largely on the manufacturer, the remaining factors depend on the sales unit. Using blockchain for traceability can help manufacturers solve these three factors.

1. Build competitive advantage by creating trust with consumers

By providing full information about the links in the supply chain, manufacturers can give consumers a comprehensive view of the origin of the product, helping to ensure product safety. Blockchain can track and trace the origin of the input process, which helps to eliminate the possibility of counterfeiting products, better control product quality, and contribute to improving the overall value of the entire supply chain.

2. Reduce the pressure of proving food safety

Blockchain also saves costs and reduces the pressure on manufacturers to prove the origin of products. For this verification to work, banks, subsidiaries and partners involved in the production process need to authenticate information for transactions in the chain.

3. Helps manage production processes better in real time

For manufacturers, Blockchain helps manage the entire process from farm to shelf in real time. All information from farmers, care, transportation, storage, processing, etc. are recorded and closely monitored by the system. This helps manufacturers better control activities in the chain, reducing the risk of food not ensuring quality. How does Blockchain trace food? In the food production process chain, there are many participating agents such as farmers, distributors, processors, retailers, etc. The main links in the seafood supply chain include:

- Providing breeds: includes information about breeds, food, medicine, machinery, etc., transaction information with farmers.

- Farming: includes information about farmers and the aquaculture process, as well as weather conditions, animal status, welfare regimes, etc.

- Processing: includes information about the factory, equipment, processing methods, product batch numbers, financial transactions between the processing unit and the distribution unit.

- Distribution: includes information about means of transport, routes, storage conditions (temperature, humidity), transportation time, transactions between distributors and retailers.

- Retail: information about each type of item, quantity, quality, storage conditions, time on shelf…

- Consumption: As the final link in the value chain, consumers can use their internet-connected phones to scan the QR code attached to the product to view all relevant information from the seed supplier to the retailer.

How does blockchain trace food?

In the food production process chain, there are many actors involved such as farmers, distributors, processors, retailers, etc. The main links in the seafood supply chain include:

1. Providing breeds: including information about breeds, food, medicine, machinery, etc., transaction information with farmers.

2. Farming: includes information about farmers and the aquaculture process, as well as weather conditions, animal status, welfare regimes, etc.

3. Processing: includes information about the factory, equipment, processing method, product batch number, financial transactions between the processing unit and the distribution unit.

4. Distribution: includes information about means of transport, routes, storage conditions (temperature, humidity), transportation time, transactions between distributors and retailers.

5. Retail: information about each type of item, quantity, quality, storage conditions, time on shelf...

6. Consumption: As the final link in the value chain, consumers can use their internet-connected phones to scan the QR code attached to the product to view all relevant information from the seed supplier to the retailer.

With Blockchain, the food supply process is made public to all actors in the chain, thereby minimizing fraud in operations and transactions, ensuring a transparent and safe economic environment for all components.

Source: https://digital.fpt.com/linh-vuc/truy-xuat-nguon-goc-voi-blockchain.html